Accelerating optimisation with validation and evaluation of mathematical models

Running experiments for the whole range of operational conditions of an ICE can be expensive and time consuming. In the engine design process this is usually impossible or lengthy and costly to do. Computational models that are validated at limited critical conditions can lead to quick engine operation optimization.

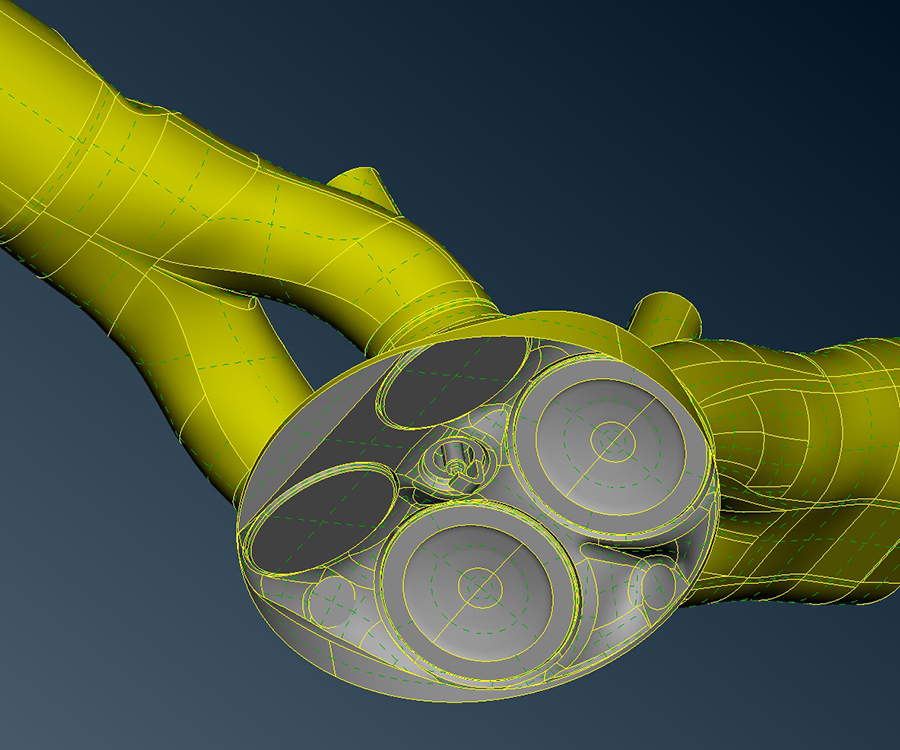

When the transparent engine is combined with compatible Computational Fluid Dynamics (CFD) software it accelerates the optimisation process. More specifically, flow field and combustion models need to be calibrated at known conditions and validated by experimental data. The optical engine experiments can help in this direction as it has well controlled geometry (stroke, bore, compression ratio, piston and engine head geometry), operational parameters (ignition and injection timing, injection duration, intake pressure, injection pressure, engine speed) and boundary conditions. Then engine simulation codes can be incorporated for more complicated engine setups focused on improving engine efficiency and emissions.