Combustion process optimization

Combustion process optimisation can by usually achieved by changing the operational parameters of ICEs when different fuels and different equivalence ratios are used.

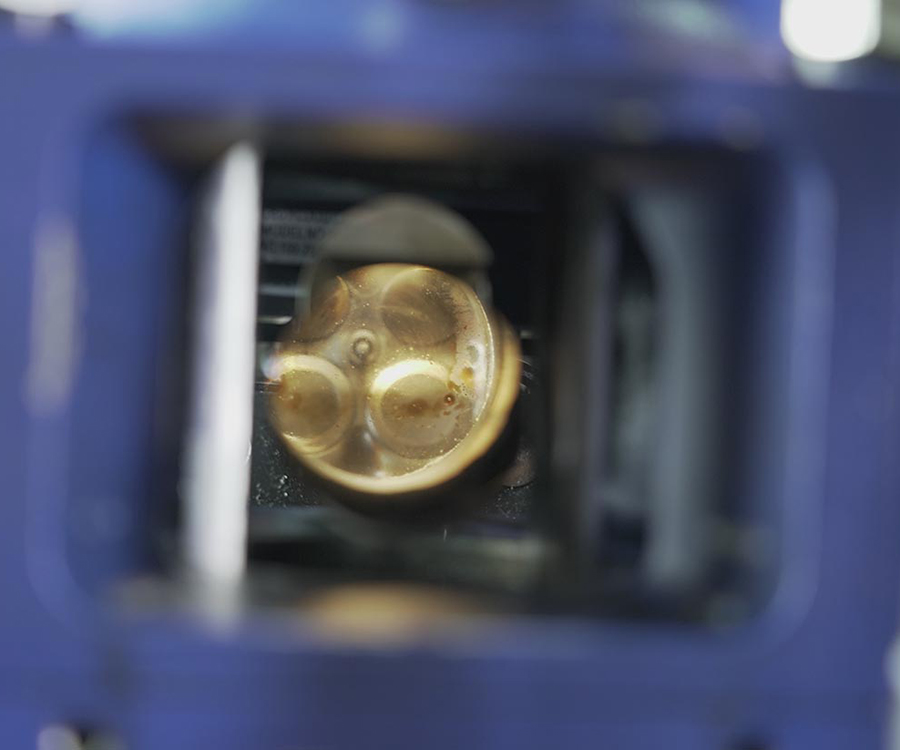

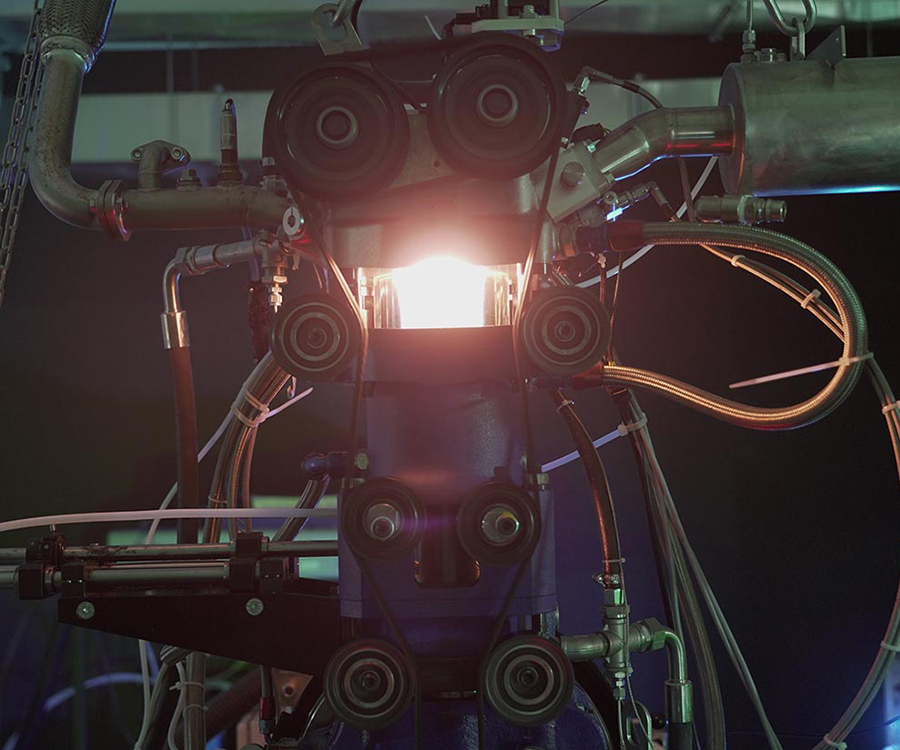

Commercial gasoline is usually blended with biofuels and there is a lot of effort by petroleum companies in developing additives that enhance engine efficiency. These “new” fuels can have different behaviour in the combustion process as their physical and chemical properties differ from the traditional ones. Additionally, current trend in ICEs combustion includes lean mixtures burning something which acts beneficially for NOx emissions. Optical engine can be tuned for all these scenarios and we can test different types of injection (PFI or GDI), different injection timings and durations (including multiple injection strategies) and different spark timings

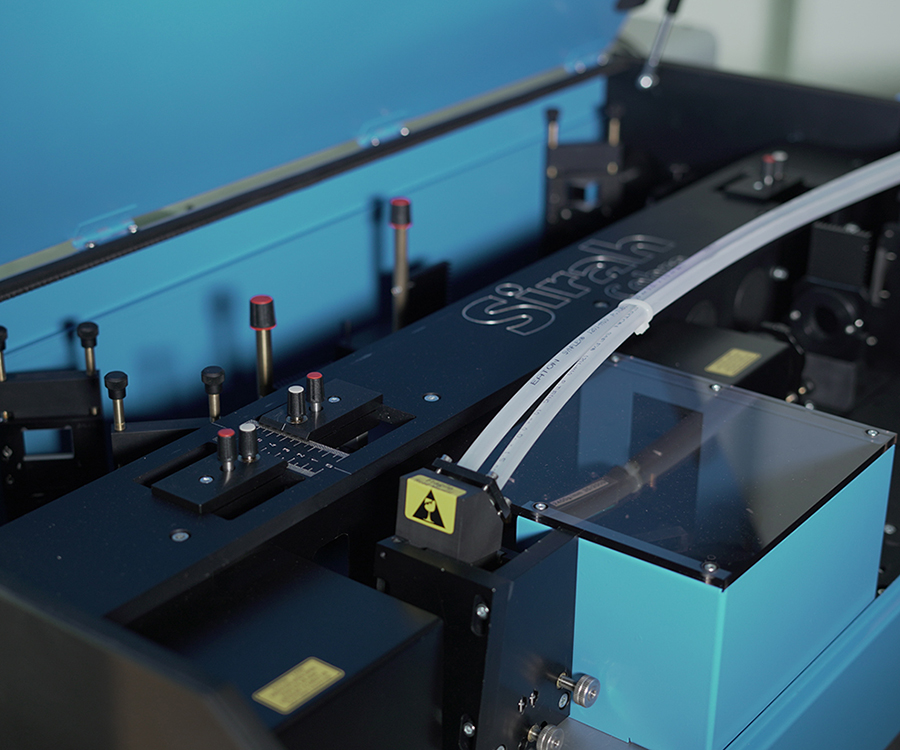

After changing the above parameters, combustion process can be evaluated by means of species measurements and visualisation. Emiited light by combustion includes a wide range of wavelengths mainly from the Infra Red (IR) to the Ultra Violet (UV) part of the spectrum. Different combustion species, each of one related to a unique property of the flame, emits at a discrete wavelength. For example, OH* is related to the heat release zones, CH* to the reaction zone and flame front and C2* to fuel rich areas. The methods we use can give spatial qualitative and quantative information about the concentration of those species inside the combustion chamber. This information can be important for engine efficiency optimisation and pollutants formation mechanisms understanding.